What are OLEDs?

In this article, we are going to discover what OLEDs are, how they work and their applications. First, let’s see the meaning of the name:

OLED is the acronym of ORGANIC LIGHT EMITTING DIODES.

Indeed, OLEDs are small light-emitting diodes made up of multiple layers of material.

If you wonder what a diode is, the answer is actually very simple: a diode is nothing more than an electronic component that allows the unidirectional flow of current (Figure 1).

Where are they used?

Nowadays, OLEDs have already found many applications and that is why we often hear about them in advertisements. In fact, industries have begun to use these components in the manufacture of displays for new televisions and light sources in general; promising not only performance improvements but also lower energy consumption.

How are they made?

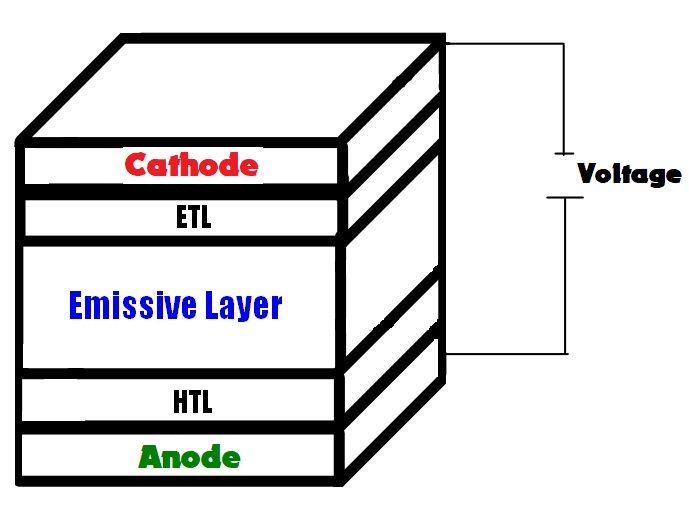

Each OLED is composed of various overlapping layers, which are placed between one anode, the entry point of the electrons, and one cathode, the exit point of the electrons (see Figure 2). Inside this pile, there are the ETL and HTL layers, (electron transfer layer and hole transfer layer respectively) which improve the charge transport. Other layers can be introduced such as the EIL and HIL layers (electron injection layer and hole injection layer) to favor charge separation. Nevertheless, the most important layer of the OLED is certainly the emissive layer. It is here, in fact, that the production of light takes place. This layer is made of organic molecules, i.e. molecules mainly based on carbon and hydrogen, but also nitrogen and oxygen.

How can they emit light?

Once we have understood the internal structure of an OLED, now, we can try to answer the question: how do actually OLEDs work?

If an external voltage is applied to an OLED, positive charges (+), called holes, and negative charges (-), called electrons, are created inside the emissive layer. The electrons migrate towards the anode, while the holes in the opposite direction, i.e. towards the cathode. The electrons flow in the external circuit and pass through the cathode and the ETL layer; when they are back to the emissive layer, they find themselves in the higher energy level of the molecule, namely in the excited state (S*). Falling inevitably to the lower energy level (ground state, S0), they emit the difference in energy between ground state and excited state in the form of light (see the animated picture below). This is the light produced in OLEDs.

Furthermore, through the right design of the organic molecules present in the OLEDs, it is possible to modulate the difference in energy between the excited state and the ground state in order to change the emission and therefore the color of the emitted light (Figure 4). Indeed, with this technique, industry has already achieved the goal to have OLEDs emitting in blue, green and red region. Those three colors, which are abbreviated RGB, are the fundamental color to build each display.

Where is now the research about OLEDs?

On the other hand, even if it looks new, OLED technology has already reached its third generation of development.1

The first generation of these components consisted of the so-called fluorescent OLEDs. These materials were based on fluorescence emission. However, the internal quantum yield of such a device was only 25%.

Therefore, in order to improve the internal quantum yield, the second generation of OLEDs was developed. This generation was based on phosphorescent OLEDs. Here, the emissive layer was made of a phosphorescent material, capable of emitting with up to 75% conversion.2

Today, however, phosphorescent OLEDs seem to have been replaced by TADF (Thermally Activated Delayed Fluorescence) OLEDs. These new OLEDs look promising with up to 100% internal quantum yield.3

Why have OLEDs become so ubiquitous in displays?

So far, in this article we have learned that OLEDs are very small diodes that emit light of the desired color. Let’s now try to understand why they have become so important in the manufacture of displays. Moreover, what is the difference with the traditional LED displays?

First of all, the use of OLEDs lets us eliminate numerous devices previously used in the manufacture of monitors, such as:

1) the backlight system, a system of lights used to create the brightness of the monitor;

2) the LCD sheet (liquid crystal display), a sheet made of liquid crystals, which allows to modulate the passage of light according to the received signal;

3) the RGB (red, green, blue) filter, which allows the formation of the basic colors of the monitors, i.e. red, green and blue, from which all colors can be formed;

Nowadays thanks to OLEDs, these three elements can all be replaced with a single compact sheet formed by numerous OLED lights in the red, green and blue spectrum (see figure comparison below), whose light intensity can be directly adjusted to create the image thanks to a controlled passage of the current.

Drag the slider to compare LED monitor (left) with OLED one (right)

The structure of these OLED monitors offers also additional benefits such as deeper black, thinner and brighter displays as well as flexible displays.

References

1) Hong, G. J., Gan, X., Leonhardt, C., Zhang, Z. G., Seibert, J., Busch, J. D., & Bräse, S. (2021). A Brief History of OLEDs—Emitter Development and Industry Milestones. Advanced Materials, 33(9), 2005630. https://doi.org/10.1002/adma.202005630

2) Wang, Q., Lucas, F., Quinton, C., Qu, Y., Rault-Berthelot, J., Jeannin, O., Yang, S., Kong, F., Kumar, S., Liao, L., Poriel, C., & Jiang, Z. (2020). Evolution of pure hydrocarbon hosts: simpler structure, higher performance and universal application in RGB phosphorescent organic light-emitting diodes. Chemical Science, 11(19), 4887–4894. https://doi.org/10.1039/d0sc01238f

3) Arjona-Esteban, A., Szafranowska, B., & Ochsmann, J. (2019). TADF Technology for Efficient Blue OLEDs: Status and Challenges from an Industrial Point of View. In IntechOpen eBooks. IntechOpen. https://doi.org/10.5772/intechopen.86534